We’re excited to share some great news from our team here at Portech Ltd. Two of our talented engineers, Hossein Shahbazi and Ehsan Alirezaei, have been published in the April 2025 issue of Advanced Materials & Processes (AMP) — the flagship magazine of ASM International, a leading voice in the materials science and surface technology world.

Their article, “Characterization of Thermal Barrier Coatings Produced Using a Novel Atmospheric Plasma Spray Torch,” highlights the work we’ve been doing to push the boundaries of thermal spray coating technology. It’s a proud moment not just for Hossein and Ehsan, but for all of us at Portech.

Why This Matters

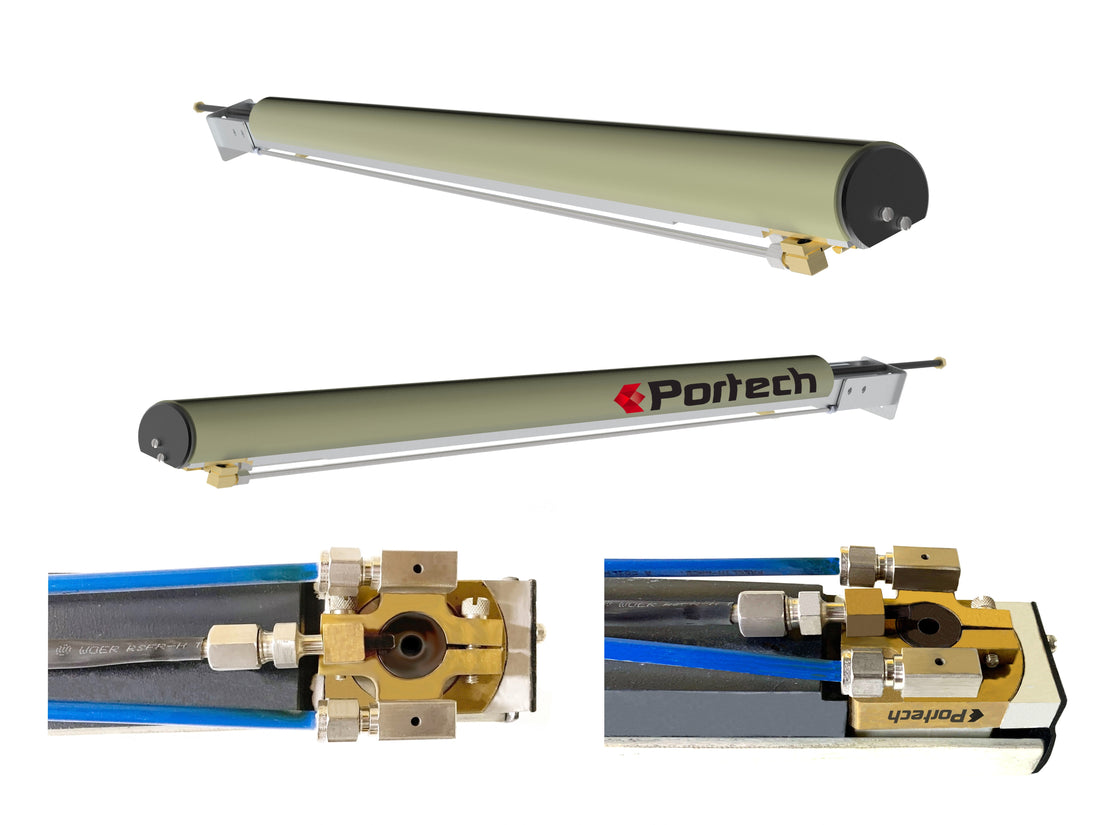

At the heart of the article is one of our latest innovations: the APS 3MB-PT-ID torch. This new atmospheric plasma spray torch was developed right here in our Ottawa facility, with a very specific goal in mind — solving the challenge of applying thermal barrier coatings (TBCs) inside tight and confined spaces, like small gas turbine components.

When working in areas with limited access — like annular combustors and transition ducts — conventional spray torches just don’t cut it. That’s where our new design comes in. It’s compact, powerful, and built to handle the heat. Literally.

What Sets It Apart

The APS 3MB-PT-ID torch delivers up to 40 kW of power and features an advanced heat protection system, which allows it to operate safely and effectively even when coating internal diameters as small as 150 mm — all while maintaining a 5 mm safety gap from the component wall.

But the real test? Performance.

In their study, Hossein and Ehsan applied a two-layer coating system — a NiCoCrAlY+HfSi bond coat and an 8 wt% YSZ ceramic topcoat, both commonly used in high-heat environments like turbines. Their results were impressive:

-

Even, uniform coating porosity

-

Strong bonding between layers

-

Average bond strength of 15.4 ± 0.7 MPa

These are exactly the kind of results needed in industries like aerospace, energy, and gas turbine repair, where durability and reliability are non-negotiable.

More Than Just a Publication

This recognition from ASM International isn’t just a nice badge of honor — it validates the hard work and deep technical knowledge that our engineering team brings to the table. It’s a testament to our commitment to engineering innovation, surface protection, and thermal spray solutions that actually make a difference in the field.

We are also proud to collaborate with the academic and research community and will be sharing more about our new partnerships and joint projects very soon.

Want to Learn More?

You can read the full article published in AMP Magazine by clicking the link below:

🔗 https://static.asminternational.org/amp/202504/42/